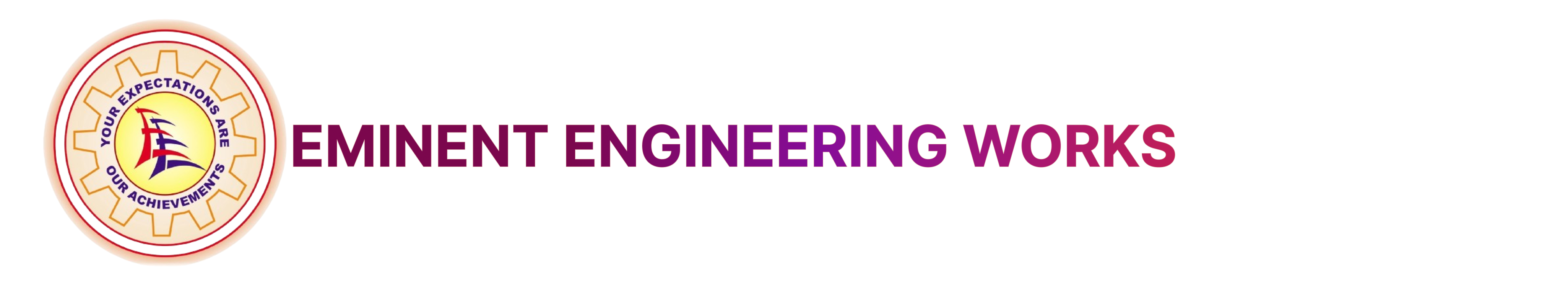

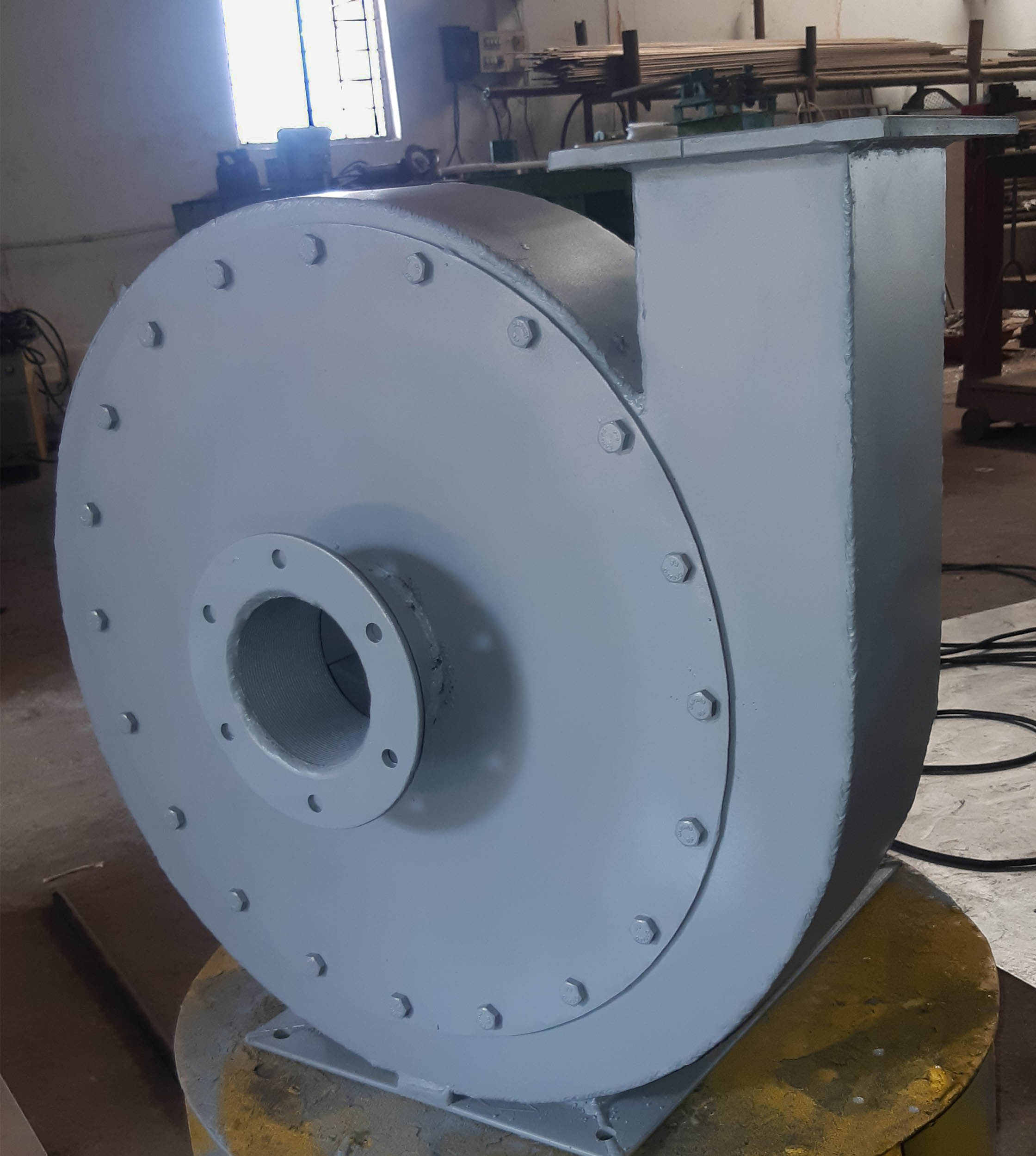

Centrifugal Blowers

Centrifugal blowers use high-speed impellers or blades to impart velocity to air or other gases. They can be single or multi-stage units. Centrifugal impeller often contain a ducted housing to direct outgoing air in a specific direction or across a heat zone. Centrifugal blowers offer a number of blade orientations, including backward curved, forward curved, inclined and radial. Blowers can be multi- or variable speed units. They are usually driven by electric motors, often through a belt and sheave arrangement. But some centrifugal blowers are directly coupled to drive motors. Fan speed can be changed to vary flow rates by resizing sheaves, using variable speed drives, etc., but dampers are even more common as a means of adjusting flow. These kinds of fans are suitable for high temperatures and low and medium blade tip speeds at high pressures. These can be effectively used for highly contaminated airstreams.

Eminent Engineering Works can design and fabricate any type of Centrifugal Blowers. All our fabrication products are complying to ASME, European Standards and each stage is strictly controlled by in-house and third party inspection. Welders are qualified as per ASME Sec IX, IBR and their WPS/PQR are available for client’s review.

Material can be used for Centrifugal Blowers:

• Carbon steel (Any Grade)

• Stainless Steel (SS 304, SS316, SS316L, etc.)